When designing spherical tanks, ensuring optimal structural integrity is paramount. Several key factors must be meticulously evaluated to guarantee the tank's ability to withstand internal and external loads. The geometry of the tank, material selection, welding methods, and environmental circumstances all contribute a role in determining its overall strength and resilience.

- Additionally, understanding the intended use of the spherical tank is crucial. For instance, tanks storing corrosive materials may require additional safeguards to ensure both structural integrity and safety.

Incorporating Piping Systems in Spherical Tank Installations: Best Practices and Challenges

Piping systems introduce unique challenges when integrated into spherical tank installations. Ensuring proper alignment and flow while minimizing stress on the spherical structure requires careful design. One best practice involves using flexible linkages to absorb thermal expansion and contraction, minimizing strain on the tank.

Furthermore, proper reinforcement of piping runs is crucial to prevent swaying or vibration that could damage the tank or interrupt operations.

A comprehensive analysis of flow rates, pressure needs, and potential risks should inform the design process.

- Regular inspections and maintenance are essential to recognize any issues with piping integrity before they become major problems.

By implementing these best practices, engineers can ensure the safe and efficient operation of spherical Industrial tanks while minimizing the complexity associated with piping system integration.

Spherical Tank Material Selection: Your Complete Resource

When designing cylindrical tanks, the choice of component is paramount. Several factors influence this decision, comprising the intended use of the tank, environmental factors, and physical requirements. Frequently used materials include carbon steel, each with its own set of benefits.

- Consider

- Carbon Steel offers corrosion resistance making it suitable in applications involving aggressive media.

On the other hand, aluminum is a more budget-friendly option, suitable in applications where corrosion resistance is not a primary concern.

Methods Employed in Constructing Vast Spherical Tanks: A Focus on Efficiency and Safety

Constructing large-scale spherical tanks presents unique challenges regarding both efficiency and safety. Engineers must carefully select construction techniques that maximize structural integrity while minimizing costs and duration. Commonly used methods include modular construction, where prefabricated units are assembled on-site, and welded plate construction, which involves forming the tank from a continuous sheet of material. Regardless the chosen method, strict adherence to safety protocols is paramount, encompassing measures against potential hazards such as explosions.

- Thorough testing and inspection procedures are essential throughout the construction process to ensure compliance with safety standards.

- Experienced personnel play a vital role in carrying out these techniques safely and effectively.

Ultimately, the success of large-scale spherical tank construction hinges on a integrated approach that prioritizes both efficiency and safety.

5. Stress Analysis of Spherical Tanks Under Operational Conditions

A comprehensive stress analysis of spherical tanks under operational conditions is crucial. This involves examining the stresses generated by various parameters, such as applied pressure, temperature variations, and seismic forces. The analysis aims to determine the magnitude of stresses acting on the tank's structure and guarantee its structural integrity under operational conditions.

Various computational methods can be employed for stress analysis, including finite element analysis (FEA). The choice of method depends on the level of detail required and the access of computational resources.

Finite Element Modeling for Spherical Tank Design Optimization

Optimizing the design of spherical tanks involves evaluating factors like stress pattern, substance properties, and manufacturing considerations. Finite element modeling (FEM) offers a powerful tool to simulate and study the characteristics of spherical tanks under various loading conditions. By discretizing the tank into smaller elements, FEM allows engineers to determine stress points, deflection, and other critical parameters. This process enables the optimization of tank structure, wall thickness, and material selection to achieve desired strength while minimizing weight and production costs.

Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Susan Dey Then & Now!

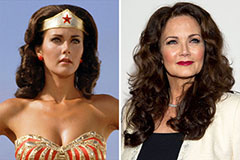

Susan Dey Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!